APET-Based Thermoformed Trays Market Trends 2025-35

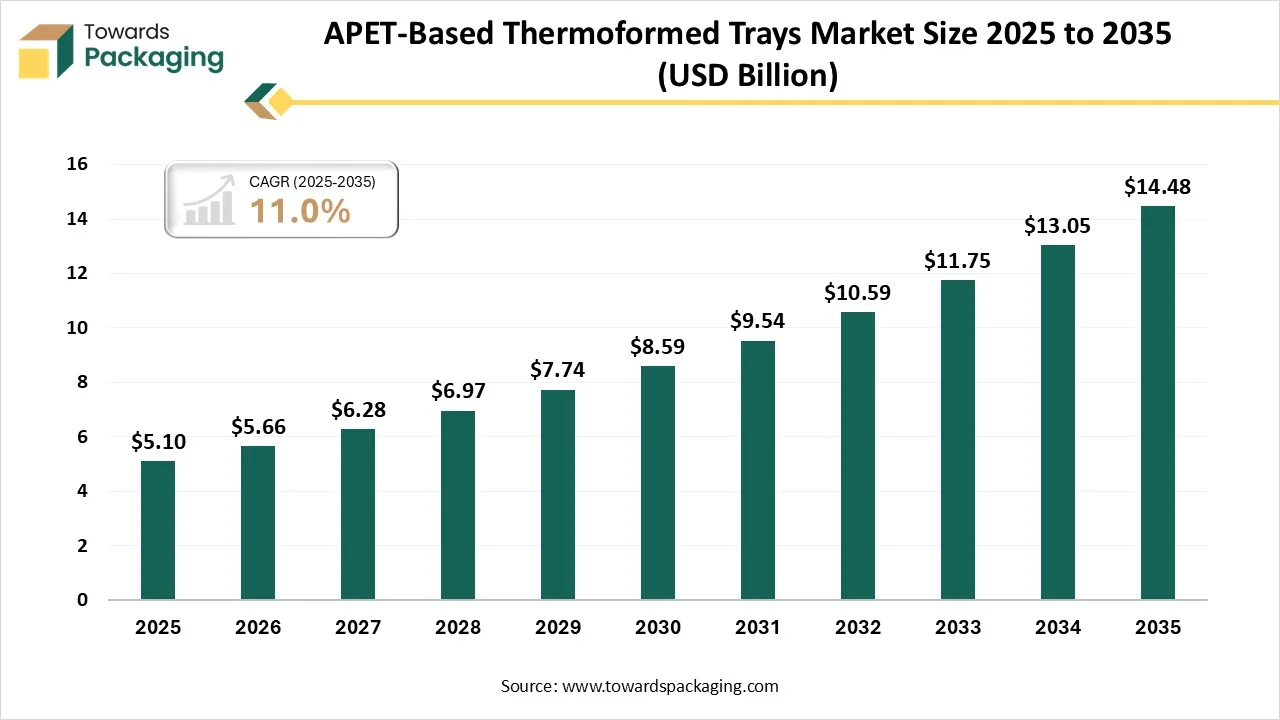

According to projections from Towards Packaging, the global APET-based thermoformed trays market is set to increase from USD 5.66 billion in 2026 to nearly USD 14.48 billion by 2035, reflecting a CAGR of 11.0% during 2026 to 2035.

Ottawa, Feb. 09, 2026 (GLOBE NEWSWIRE) -- The global APET-based thermoformed trays market hit USD 5.10 billion in 2025, with current forecasts pointing to USD 14.48 billion by 2035, according to Towards Packaging, a sister firm of Precedence Research. The APET-based thermoform trays industry is driven by rising demand for transparent, lightweight, and recyclable packaging across food, medical, and consumer goods sectors.

Request Research Report Built Around Your Goals: sales@towardspackaging.com

What are APET-based Thermoformed Trays?

APET-based thermoform trays are rigid packaging solutions made from amorphous polyethylene terephthalate, offering high clarity, strength, and recyclability. Market growth is driven by rising demand for transparent food packaging, extended shelf life, lightweight materials, regulatory support for recyclable plastics, convenience food consumption, and increasing preference for cost-effective and sustainable packaging solutions across industries.

Get All the Details in Our Solutions - Access Report Sample: https://www.towardspackaging.com/download-sample/5958

Private Industry Investments for APET-Based Thermoformed Trays:

- Amcor plc launched AmSecure, an APET-based material for healthcare trays, to provide a cost-effective and more sustainable alternative to PETG with comparable performance.

- Toppan Holdings Inc. acquired Sonoco Products Company's Thermoformed and Flexibles Packaging business for approximately $1.8 billion, aiming to become a global leader in sustainable packaging solutions and expand its market presence.

- Graham Partners, a private investment firm, invested in EasyPak, LLC, a thermoformed packaging provider, to build a top-tier mid-sized thermoformer focused on sustainable packaging options and the healthy food market.

- Nelipak Healthcare Packaging continues to design, develop, and manufacture custom cleanroom-produced APET thermoformed trays to provide superior protection for medical devices and pharmaceuticals.

-

Tesco, in collaboration with Faerch Group, launched a "tray-to-tray" initiative to recycle used APET food trays back into new food-grade trays, closing the loop on plastic packaging for its chilled ready meals.

What Are the Latest Key Trends in the APET-Based Thermoformed Trays Market?

1. Sustainability and Recycled Content Innovation

The market is increasingly prioritizing sustainable packaging, with companies incorporating recycled PET (rPET) and designing fully circular APET trays to reduce reliance on virgin plastics and enhance recyclability. Advanced sorting and recycling technologies further support circular economy goals by improving rPET quality, aligning with regulatory and consumer pressures for eco-friendly solutions.

2. Smart & Functional Packaging Integration

APET thermoform trays are evolving beyond simple containment to include smart packaging features like QR codes, sensors, and antimicrobial surfaces. These enhancements improve product safety, traceability, and consumer engagement, especially in food and healthcare sectors where freshness indicators and traceability are increasingly valued.

3. Automation and Manufacturing Efficiency

Advances in thermoforming equipment, such as automated forming lines with improved precision, reduced waste, and faster cycle times, are boosting production efficiency. Manufacturers are adopting robotics and intelligent machinery to improve throughput and consistency while lowering costs, meeting growing demand with leaner operations and higher quality output.

4. Lightweighting and Material Optimization

Thermoformers are leveraging material science to produce thinner yet stronger APET trays, reducing material usage and transportation emissions without compromising structural integrity. Lightweighting helps manufacturers lower costs and environmental impact while maintaining high barrier and clarity properties needed for food and consumer goods packaging.

5. Customization & Premiumization of Packaging

Brand owners are demanding tailored tray designs, custom shapes, and high-quality finishes to enhance shelf appeal and differentiate products. This trend supports premium product positioning and accommodates versatile applications from ready meals to healthcare kits, driven by consumer preferences for convenience and unique packaging experiences.

What is the Potential Growth Rate of the APET-Based Thermoformed Trays Industry?

The growth of the APET-based thermoform trays industry is driven by rising demand for transparent and hygienic food packaging, increasing consumption of ready-to-eat meals, and strong preference for lightweight and recyclable materials. Favorable regulations supporting sustainable plastics, cost efficiency, excellent barrier properties, and expanding applications in food, medical, and retail packaging further support market expansion.

More Insights of Towards Packaging:

- Rigid Paper Containers Market Size and Segments Outlook (2026–2035)

- Rigid Substrate Market Size, Trends and Competitive Landscape (2026–2035)

- Vehicle Wrapping PVC Film Market Size and Segments Outlook (2026–2035)

- Cell Culture Media Storage Containers Market Size, Trends and Segments (2026–2035)

- Medication Dispensing and Packaging Systems Market Size and Segments Outlook (2026–2035)

- Nanocrystal Packaging Coating Market Size, Trends and Segments (2026–2035)

- Medical Transport Box Market Size, Trends and Competitive Landscape (2026–2035)

- Barrier Coatings For Packaging Market Size, Trends and Competitive Landscape (2026–2035)

- Smart Tag Packaging Market Size, Trends and Competitive Landscape (2026–2035)

- Beverage Container Market Size, Trends and Segments (2026–2035)

- Beauty Supplements Packaging Market Size, Trends and Regional Analysis (2026–2035)

- Nano Enabled Packaging Market Size, Trends and Competitive Landscape (2026–2035)

- In Vitro Diagnostics Packaging Market Size, Trends, Segments, Regional Outlook, Competitive Landscape & Trade Analysis 2025-2035

- Wet Glue Labelling Machine Market Size, Trends and Segments (2026–2035)

- Self-Adhesive Labels Market Size, Trends and Regional Analysis (2026–2035)

- Packaging Machinery Market Size, Trends, Share, Trends, Segments, and Regional Insights (NA, EU, APAC, LA, MEA)

- Fragrance Packaging Market Size, Trends, Key Segments, and Regional Dynamics with Manufacturers and Suppliers Data

- Food Packaging Equipment Market Size and Segments Outlook (2026–2035)

- PCR-Rich Glass Container Market Size, Trends and Competitive Landscape (2026–2035)

- Aluminum-Free High-Barrier Films Market Size, Trends and Segments (2026–2035)

Regional Analysis:

Who is the leader in the APET-Based Thermoformed Trays Market?

North America dominates the market due to strong demand from the packaged food and ready-meal sectors, advanced thermoforming infrastructure, and early adoption of recyclable packaging solutions. Stringent food safety standards, high consumer preference for transparent and convenient packaging, the presence of major packaging manufacturers, and well-established recycling systems further support regional market leadership.

U.S. APET-Based Thermoformed Trays Market Trends

The U.S. leads the North American market due to its large packaged food and foodservice industries, high consumption of ready-to-eat products, and strong presence of major packaging manufacturers. Advanced thermoforming technologies, strict food safety regulations, widespread retail networks, and growing adoption of recyclable and sustainable packaging solutions further strengthen the country’s dominant position.

How is the Opportunistic is the Rise of the Asia Pacific in the APET-Based Thermoformed Trays Industry?

Asia-Pacific is the fastest-growing region in the market due to rapid urbanization, rising disposable incomes, and increasing consumption of packaged and convenience foods. Expanding food processing industries, growth of organized retail and e-commerce, cost-effective manufacturing, and improving awareness of recyclable packaging materials further accelerate market growth across emerging economies.

China APET-Based Thermoformed Trays Market Trends

China dominates the Asia-Pacific market due to its large-scale food processing industry, expanding ready-to-eat food consumption, and strong manufacturing capabilities. The presence of numerous thermoforming and PET material suppliers, cost-efficient production, rapid growth of organized retail and e-commerce, and increasing adoption of recyclable packaging solutions further strengthen China’s leading position in the regional market.

How Big is the Success of the Europe APET-Based Thermoformed Trays Industry?

Europe is a notably growing region in the market due to strong regulatory support for recyclable and circular packaging materials. Strict environmental policies encourage the use of mono-material PET trays with high recycled content. Growing demand for packaged and fresh foods, well-developed recycling infrastructure, technological advancements in thermoforming, and rising consumer awareness toward sustainable and food-safe packaging solutions further support market growth across the region.

Join now to access the latest packaging in industry segmentation insights with our Annual Membership: https://www.towardspackaging.com/get-an-annual-membership

Segment Outlook

Product Type Insights

What made the Food Trays Segment Dominant in the APET-Based Thermoformed Trays Market?

The food tray segment dominates the global market due to high demand for transparent, hygienic, and lightweight packaging in fresh food, meat, bakery, and ready-meal applications. APET trays offer excellent product visibility, strong barrier properties, cost efficiency, and compatibility with food safety regulations, making them widely preferred by food processors and retailers.

The bakery and confectionery trays segment is the fastest-growing in the market due to rising consumption of packaged baked goods and sweets. APET trays provide high clarity, rigidity, and moisture resistance, enhancing product appeal and freshness. Growing demand for premium presentation, convenience packaging, and extended shelf life further accelerates adoption in this segment.

Application Insights

How the Fresh Food Packaging Dominated the APET-Based Thermoformed Trays Market?

The fresh food packaging segment dominates the market due to strong demand for hygienic, transparent, and protective packaging for meat, poultry, seafood, fruits, and vegetables. APET trays offer excellent clarity, rigidity, and barrier performance, enabling product visibility and freshness. Growing consumer preference for packaged fresh foods and strict food safety standards further support segment dominance.

The ready-to-eat or convenience food segment is the fastest-growing segment in the market due to busy lifestyles, urbanization, and rising demand for packaged meals. APET trays support microwave compatibility, product visibility, and portion control. Growth of modern retail, food delivery services, and preference for hygienic, tamper-resistant packaging further accelerates adoption.

End-User Insights

How Food and Beverage Manufacturers Segment Dominates the APET-Based Thermoformed Trays Market?

The food and beverage manufacturers dominate the market due to high-volume demand for hygienic, transparent, and cost-effective packaging. APET trays meet strict food safety requirements, offer excellent product visibility, and support extended shelf life. Widespread use in fresh, bakery, dairy, and ready-to-eat products further strengthens this segment’s dominance.

The retail and supermarket segment is the fastest growing in the s market due to increasing consumer preference for packaged and ready-to-eat products. APET trays offer high product visibility, convenience, and extended shelf life, supporting attractive in-store presentation. Growing modern retail chains and organized supermarkets further accelerate segment adoption.

Elevate your packaging strategy with Towards Packaging. Enhance efficiency and achieve superior results - schedule a call today: https://www.towardspackaging.com/schedule-meeting

Recent Breakthroughs in APET-Based Thermoformed Trays Market

- In October 2025, Amcor plc, a globally leading packaging company, announced the launch of its AmSecure APET‑based thermoformed trays and rollstock platform as part of its HealthCare packaging portfolio. The new solution is engineered to serve the demanding requirements of the medical and pharmaceutical industries, offering performance comparable to traditional PETG materials while improving cost efficiency, clarity, durability, and recyclability.

- In July 2025, UK packaging specialist Alma Products Ltd launched a new range of bespoke thermoformed tray solutions, designed for food packaging sectors including bakery, fresh produce, meat, and ready meals. These trays are made using high‑performance materials such as APET, offering customizable shapes, multiple compartments, and enhanced presentation for retail bakery and confectionery products.

Top Companies in the Global APET-Based Thermoformed Trays Market & Their Offerings:

Tier 1:

- Amcor plc: Provides high-clarity, healthcare-grade APET trays as a recyclable alternative to PETG for medical device sterilization.

- Sonoco Products Company: Recently exited this market by selling its thermoformed packaging business to TOPPAN Holdings Inc. in early 2025.

- Pactiv Evergreen Inc.: Offers a massive selection of APET supermarket and processor trays for fresh proteins, produce, and food service.

- WestRock Company: Primarily focuses on polymer-coated paperboard trays designed to replace traditional plastic thermoformed options in frozen and chilled meals.

- Placon Corporation: Specializes in food and medical APET trays made from their proprietary EcoStar recycled material containing up to 100% post-consumer content.

- Anchor Packaging: Manufactures high-clarity APET trays for the deli and "grab-and-go" segments, featuring tamper-evident and leak-resistant designs.

-

D&W Fine Pack: Supplies a broad variety of PET thermoformed trays and lids specifically tailored for catering, bakery, and deli display applications.

Tier 2:

- Sealed Air Corporation

- Sabert Corporation

- Genpak LLC

- Berry Global Inc.

- Winpak Ltd.

- TPL Plastics

- Ampac

- Ampacet Corporation

- Schur Flexibles Group

- Pregis

- DS Smith

- Smurfit Kappa Group

- Clear Lam Packaging

Segment Covered in the Report

By Product Type

-

Food Trays

- Fresh

- Prepared

- Readymeal

- Chilled

- Frozen

-

Bakery & Confectionery Trays

- Bakery

- Confectionery

- Pastry

- Dessert

- Chocolates

-

Meat & Seafood Trays

- Meat

- Poultry

- Seafood

- Fish

- Shellfish

-

Fruit & Vegetable Trays

- Fruits

- Vegetables

- Produce

- Freshcut

- Organic

-

Medical & Healthcare Trays

- Medical

- Healthcare

- Sterile

- Diagnostic

- Pharmaceutical

By Application

- Fresh Food Packaging

- Ready-to-Eat / Convenience Foods

- Retail Ready Packaging

- Industrial & Bulk Packaging

- Non-food Applications (Medical, Electronics)

By End-Use Industry

- Food & Beverage Manufacturers

- Retail & Supermarkets

- Food Service & Catering

- Healthcare & Pharmaceutical

By Region

North America:

- U.S.

- Canada

- Mexico

- Rest of North America

South America:

- Brazil

- Argentina

- Rest of South America

Europe:

- Western Europe

- Germany

- Italy

- France

- Netherlands

- Spain

- Portugal

- Belgium

- Ireland

- UK

- Iceland

- Switzerland

- Poland

- Rest of Western Europe

Eastern Europe

- Austria

- Russia & Belarus

- Türkiye

- Albania

- Rest of Eastern Europe

Asia Pacific:

- China

- Taiwan

- India

- Japan

- Australia and New Zealand,

- ASEAN Countries (Singapore, Malaysia)

- South Korea

- Rest of APAC

MEA:

- GCC Countries

- Saudi Arabia

- United Arab Emirates (UAE)

- Qatar

- Kuwait

- Oman

- Bahrain

- South Africa

- Egypt

- Rest of MEA

Invest in Our Premium Strategic Solution: https://www.towardspackaging.com/checkout/5958

Request Research Report Built Around Your Goals: sales@towardspackaging.com

About Us

Towards Packaging is a global consulting and market intelligence firm specializing in strategic research across key packaging segments including sustainable, flexible, smart, biodegradable, and recycled packaging. We empower businesses with actionable insights, trend analysis, and data-driven strategies. Our experienced consultants use advanced research methodologies to help companies of all sizes navigate market shifts, identify growth opportunities, and stay competitive in the global packaging industry.

Stay Connected with Towards Packaging:

- Find us on Social Platforms: LinkedIn | Twitter | Instagram | Threads

- Subscribe to Our Newsletter: Towards Sustainable Packaging

- Visit Towards Packaging for In-depth Market Insights: Towards Packaging

- Read Our Printed Chronicle: Packaging Web Wire

-

Get ahead of the trends – follow us for exclusive insights and industry updates:

Pinterest | Medium | Tumblr | Hashnode | Bloglovin | LinkedIn – Packaging Web Wire | Globbook | Substack | Bluesky | Justdial | Crunchbase | TrustPilot | Bizcommunity - Contact: APAC: +91 9356 9282 04 | Europe: +44 778 256 0738 | North America: +1 8044 4193 44

Our Trusted Data Partners

Precedence Research | Towards Healthcare | Towards Food and Beverages | Towards Chemical and Materials | Healthcare Webwire | Packaging Webwire | Precedence Research Insights

Towards Packaging Releases Its Latest Insight - Check It Out:

- Lightweight Aluminum Beverage Cans Market Size, Trends and Regional Analysis (2026–2035)

- Recyclable Polyethylene-based Laminates Market Size and Segments Outlook (2026–2035)

- Agricultural Films Market Size, Trends and Regional Analysis (2026–2035)

- Recycled PET Bottles Market Size, Trends and Competitive Landscape (2026–2035)

- U.S. Sustainable Packaging Market Size, Trends and Competitive Landscape (2026–2035)

- Cardboard Sheet Market Size, Trends and Segments (2026–2035)

- Non-cushioned Mailers Market Size, Trends and Competitive Landscape (2026–2035)

- Aerosol Cans Market Size, Trends and Segments (2026–2035)

- North America Flexible Packaging Market Size, Trends and Regional Analysis (2026–2035)

- BOPP Films Market Size, Trends and Competitive Landscape (2026–2035)

- Protective Films Market Size, Trends and Segments (2026–2035)

- Parenteral Packaging Market Size, Trends and Regional Analysis (2026–2035)

- Converted Flexible Packaging Market Size, Trends and Competitive Landscape (2026–2035)

- Compostable Tableware Market Size, Trends and Regional Analysis (2026–2035)

- Trigger Spray Bottle Market Size, Trends and Competitive Landscape (2026–2035)

- Plastic Container Market Size, Trends and Regional Analysis (2026–2035)

- Temperature Controlled Packaging Solutions Market Size, Trends and Segments (2026–2035)

- Biodegradable Cutlery Market Size, Trends and Competitive Landscape (2026–2035)

- Specialty Films Market Size, Trends and Competitive Landscape (2026–2035)

- Corrugated Bubble Wrap Market Size, Trends and Regional Analysis (2026–2035)

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.